A&K Development Co. & Pacific Metal Fab, LLC

Cleaner Air Oregon ProfileHexion, Inc.

As part of the Cleaner Air Oregon process, each facility has a dedicated web page to provide communities access to facility information and updates on where it is involved in the process.

- Each step of the CAO risk assessment process has a section that includes LRAPA’s communications and deliverables from the facility.

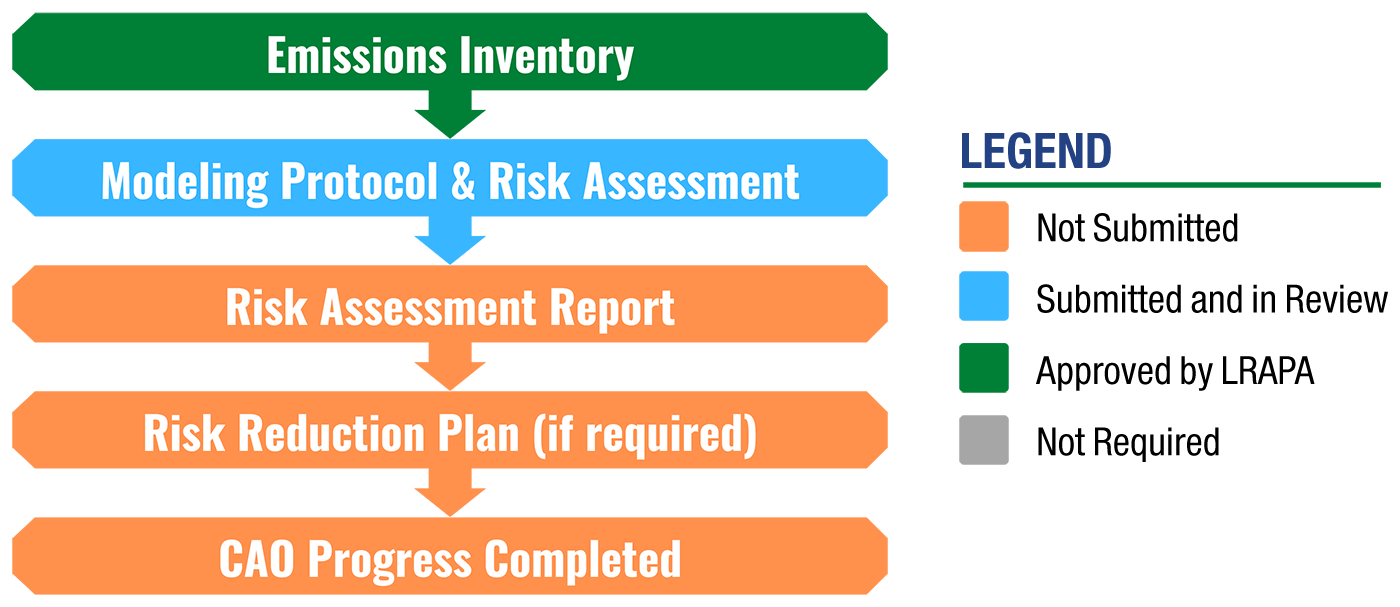

- A color-coded graphic shows where a facility is in the Cleaner Air Oregon Process.

- For additional information and history of the program, visit the DEQ Cleaner Air Oregon website.

| Document Type | Anticipated Submittal Date | Approval Date |

|---|---|---|

| Emissions Inventory | 08/05/2025 | 08/21/2025 |

| Modeling Protocol | 11/20/2025 | TBD |

| Risk Assessment Work Plan | TBD | TBD |

| Risk Assessment Report | TBD | TBD |

| Risk Reduction Plan | TBD - if required | TBD - if required |

| CAO Completed | TBD | TBD |

Emissions Inventory

July 19, 2024: A&K Dev. Co. & Pacific Metal Fab submit ACDP application for new Junction City location and begin entry to CAO program

August 5, 2025: A&K Dev. Co & Pacific Metal Fab submits their final Emissions Inventory to LRAPA

- A&K Dev. Co.’s Final Emissions Inventory

August 21, 2025: LRAPA Approves Emission Inventory

- LRAPA’s Approval Letter for A&K Dev. Co’s Emission Inventory

Modeling Protocol & Risk Assessment

- LRAPA’s letter approving extension to submit modeling protocol and risk assessment workplan.

November 20, 2025: A&K Development Co. & Pacific Metal Fab. submit modeling protocol and risk assessment workplan.

- A&K Development Co. & Pacific Metal Fab’s modeling protocol and risk assessment workplan.

Risk Assessment Report

Risk Reduction Plan

CAO Progress Completed

FACILITY

Site Address

135 E 1st Ave.

Junction City, OR 97448

Current Air Permit

Permit Type: Simple ACDP

Source Number: 200059

- Air Permit link coming once issued

- Review Report link coming once issued

LRAPA Contact

Max Hueftle

541-736-1056, ext. 231

Site Address

Springfield, OR

Current Air Permit

Source Number: 200510

LRAPA Contact

541-736-1056, ext. 236

Legend

Facility

Emissions Inventory

- LRAPA’s call in letter to Hexion, Inc.

January 29, 2021: Hexion requested an extension on the submittal date for the Emission Inventory because they have a new owner audit agreement with US EPA related to their Toxic Release Inventory emissions. This audit may affect Hexion’s emission calculations of compounds regulated by Cleaner Air Oregon

- Hexion’s Emission Inventory extension request letter.

February 12, 2021: After confirming with US EPA that Hexion is participating in a new owner audit agreement, LRAPA granted an extension on the due date for the Emission Inventory.

- LRAPA’s extension request response letter.

June 18, 2021: Hexion requested a second extension to the submittal date for the Emission Inventory because US EPA extended the due date for completion of the TRI new owner audit report.

- Hexion’s second Emissions Inventory extension request letter.

June 29, 2021: After confirming that US EPA has extended the due date for the TRI new owner audit report, LRAPA granted a second extension of the submittal date of the Emission Inventory.

- LRAPA’s second extension request response letter.

October 25, 2021: LRAPA extends Hexion’s Emissions Inventory to aligned with a December 10, 2021, due date listed in Stipulation and Final Order (SFO) No. 21-3839 signed on September 3, 2021.

- LRAPA’s third extension request response letter.

December 10, 2021: Hexion submits their emissions inventory.

- Hexion’s Compiled CAO Inventory.

- Hexion’s AQ520 Form.

March 7, 2022 and March 11, 2022: LRAPA reviewed Hexion’s submitted emissions inventory and requested modifications and clarifications. LRAPA expects a response to these requests by June 1, 2022.

Modeling Protocol & Risk Assessment

Risk Assessment Report

Hexion, Inc. – was called in into the Cleaner Air Oregon Program in January of 2021 and entered the Emissions Inventory Step of the Cleaner Air Oregon process. This field will be updated once the facility reaches this portion of CAO.